Five Industries that use TCB-Arrow Plastic Injection Moulding

Plastic injection moulding is one of the most versatile manufacturing methods available, used by a wide range of industries to produce various parts.

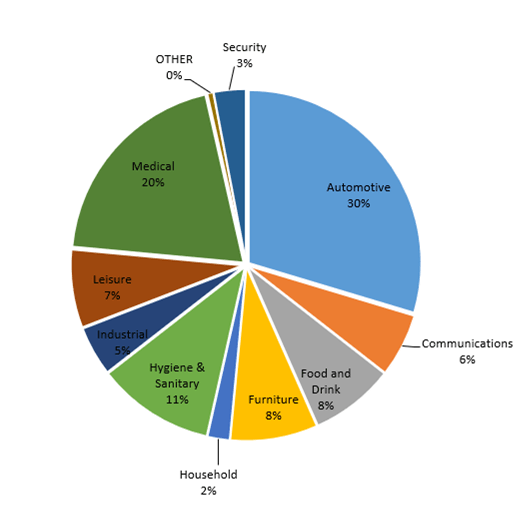

From small to large parts, plastic injection moulding mass-produces cost-effective and high-precision parts. As an established organisation that has been around for over 35 years, we offer solutions across all markets including Medical, Aerospace, Automotive, Defence, Industrial market sectors and more. In this blog, we take a closer look at the products we produce for five different sectors.

Automotive

While the automotive industry has seen a lot of change over the last decade or so, one thing that has remained constant in the industry is its use of plastic injection moulding. We regularly supply products such as ignition leads, automotive insulator boots, seals and grommets, as well as car number plate components, of which we produce over 4 million each year. Plastic injection moulding allows for these items to be mass-produced to a high quality.

Food and Drink

Many products used in everyday life are made through injection moulding, and that includes products for the

food and drink sector. From vending machine components such as cup delivery systems to simulant devices and anti-spill drink covers, at TCB-Arrow we supply an array of products to the food and drink sector.

Medical

We manufacture single-use disposable and reusable parts in both LSR and Thermoplastics for the medical industry. These include stoma care products, enema connectors, eye shields and airway management components. During the pandemic, we also helped by producing PPE, developing a clinical and general applications PPE visor shield.

Banking Security

We work closely with the security industry to produce components for banking security devices. We are experienced in producing products such as security system components for ATM banknote cassettes.

Industrial

Our experience in producing high tolerance parts, material selection and complex tooling means we can produce parts for the industrial sector. We recently produced RFID tags for a customer so that they could put an asset tag on all equipment to track its movements in and out of site. In addition to this, we produce conversion film end protector plates, pallet corner protectors and articulated protector tracks for robotics.

These are just a few examples of the industries we work with, however, the possibilities with plastic injection moulding are endless. Our list of industries is growing more and more as companies realise the benefits of this method of production.

If you have a question or query, please get in touch with our 24/7 production facility and one of our experienced team members will be happy to help. If you are looking for a price, please complete our Quote Request Form.