Why Plastics?

With strides being made to move towards greener manufacturing, a common question is “Why do we continue to produce and use plastics?” After all, they don’t have the best reputation as sustainable materials.

However, thanks to developments in the industry, this isn’t necessarily true anymore as more sustainable practices are emerging. This is just one of many of the benefits of plastics in manufacturing, which include:

They’re Non-conductible

Plastics do not conduct electrical or thermal energy well, which makes them great insulators. These insulating properties are what protect us from electrical shocks and burns, and help to keep us safe.

This insulation can help to keep food and drink hot or cold, as it allows heat to be either kept inside or outside of containers - which wouldn’t be possible without plastics.

They’re Durable

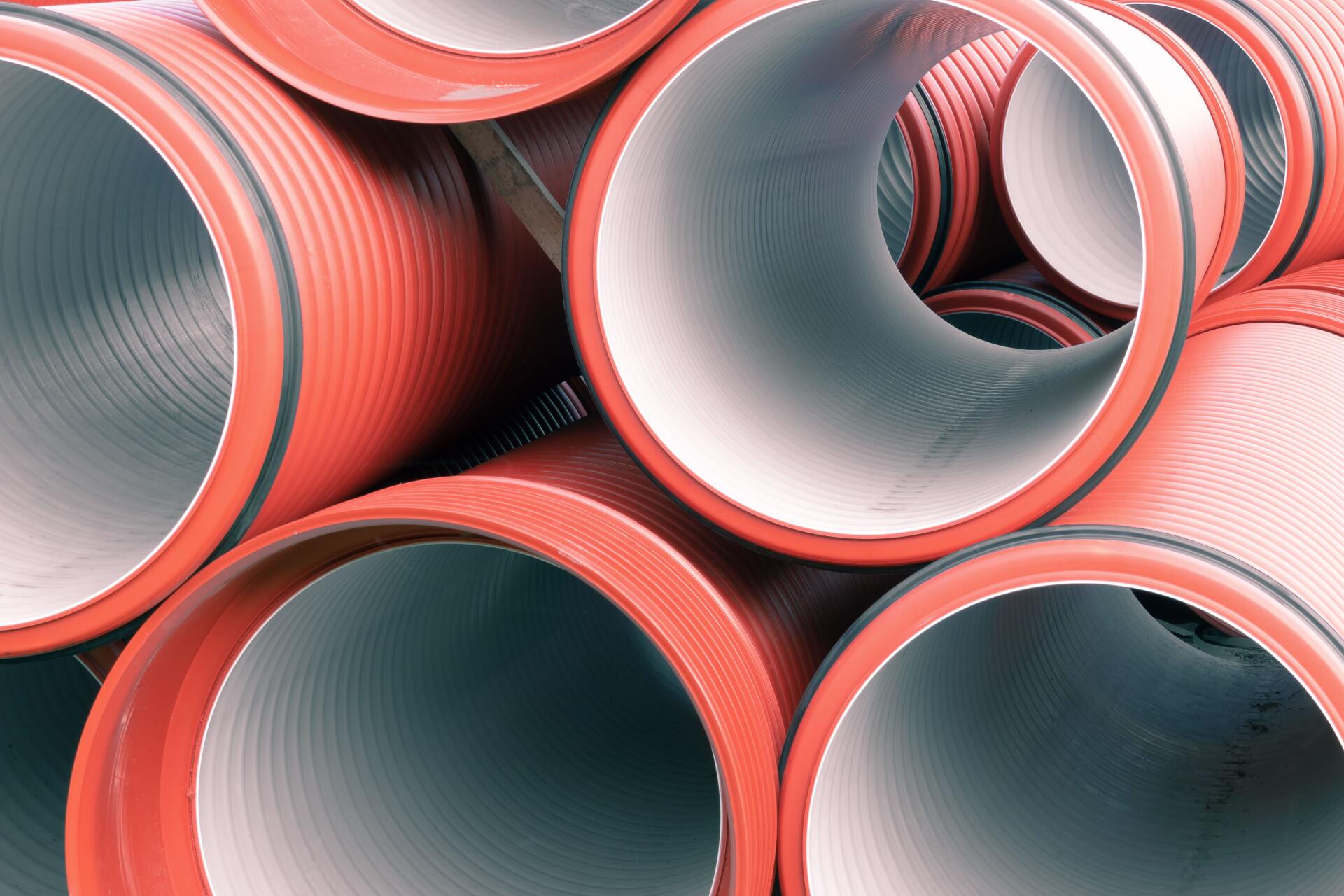

When applied to single or short-lived uses, or when plastics aren’t recycled or disposed of appropriately, the durability of plastics can be harmful to the environment. However, the strong and robust nature of some plastics can also be a huge positive when it comes to longer-term applications.

As they can withstand pressure, wear and damage for longer periods of time, certain plastics are actually necessary for long-term or continued use.

They’re Becoming more Sustainable & Recyclable

Despite the fact that many plastics are derived from fossil fuels, the ways in which they can be manufactured are changing and plastics are also becoming easier to recycle.

For example, out of the entirety of the world’s oil production, plastics only use 4% - the rest goes towards transport, heat and energy. Additionally, there are some manufacturers who have experimented with plant-based feedstocks as an alternative and have coined these as Bioplastics.

Although these provide a more sustainable raw material with an almost limitless supply, the wider context of producing Bioplastics needs to be considered (such as the required amounts of chemical and land use, as well as water.)

They are also not always biodegradable, and often need industrial applications to be composted. These are all factors that are important to take into account when considering the use of Bioplastics.

On the other hand, there is an upside to all other plastics: each has the ability to be recycled, provided that the facilities are available and the consumer/manufacturer is willing to do so. Of course, some plastics are easier to recycle than others, as often combined materials are more complicated to break down.

Thermoplastics are the easiest to recycle, as they can be easily shredded, melted and reprocessed. However, there are many other ways in which plastic recycling can be difficult.

Of course, the best way in which to use plastic products overall is to reuse and look after them well for as long as possible, and then finally recycle them when they’re no longer practical to keep. This is something that can be made possible by skilled designers and manufacturers, as they can produce robust and long-lasting materials which are then easily recyclable at the end of their lifespan.

At

TCB-Arrow, our experienced team is constantly striving towards the cleaner and greener manufacturing of plastic products. Get in touch with us to discuss your requirements now.

At TCB-Arrow, we have over 35 years of experience in selecting, applying and combining the right additives to achieve the perfect plastic products for our customers. Get in touch with our helpful team to find out more.