uPVC vs PVC

Unplasticised Polyvinyl Chloride (uPVC) and Polyvinyl Chloride (PVC) are each commonly used materials in both manufacturing and construction, but what’s the difference?

Usage

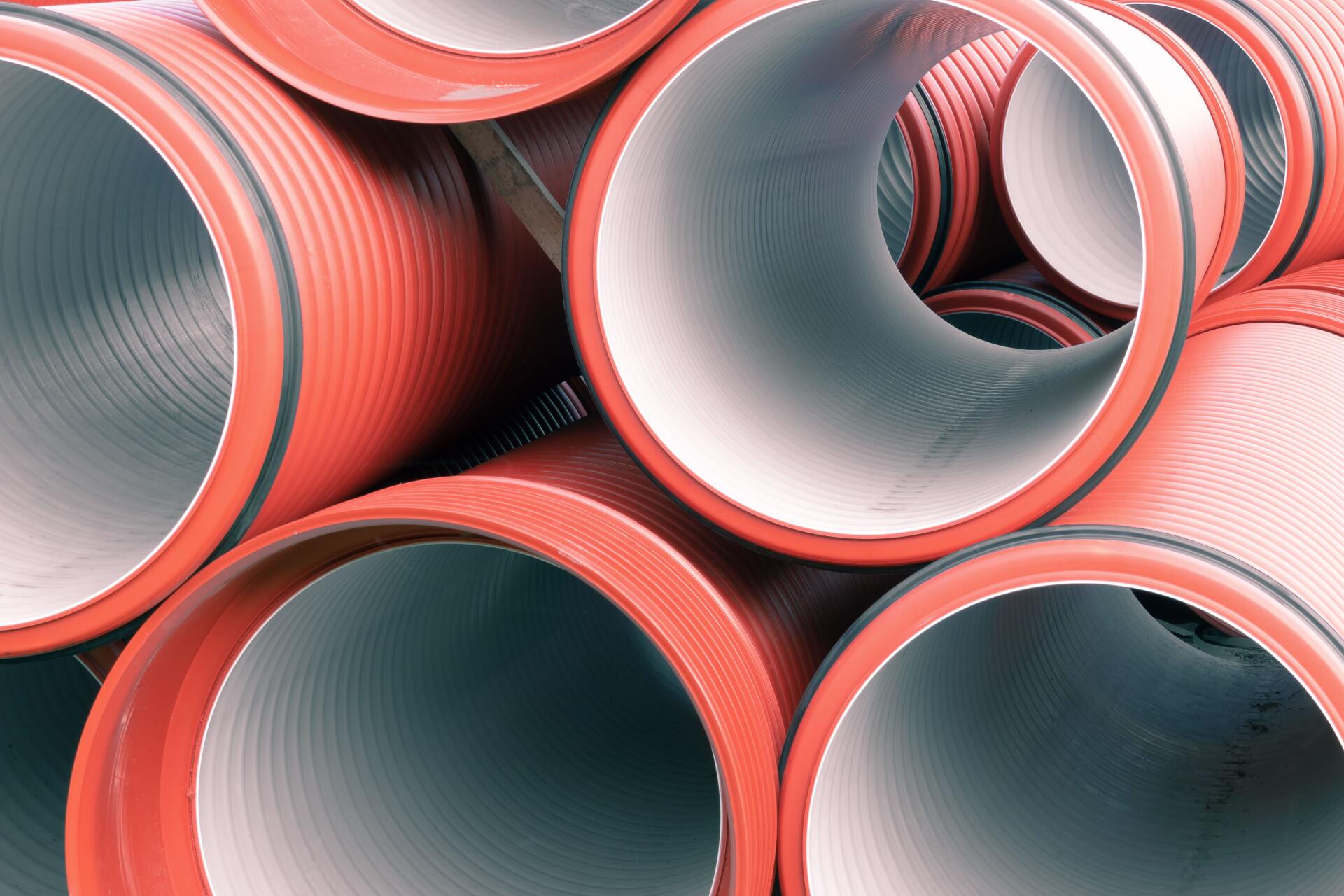

Due to the differences in the durability of each material, they’re most commonly used for different purposes. For example, the more durable and rigid nature of uPVC calls for more uses in construction, such as window frames, plumbing and drainage products.

The softer nature of PVC makes it more suitable for the manufacturing of pipes, cable insulation, clothes and toys. This also is a result of its flexibility, which can make it much easier to work with when it comes to the manufacturing of plastic parts such as these. In addition to its lower cost, this adds to the popularity of PVC moulding.

Properties

Due to the fact that uPVC is highly resistant to chemicals and is strong and stable, it’s often used as a substitute for wood in construction. It’s versatile in the ways it can be produced, so can be made in many different colours and to even appear as other materials, (such as wood,) which adds to its popularity. Additionally, it can achieve smooth inner walls, so it is used for most plastic piping as this helps to encourage water flow.

However, PVC acts as a better replacement for copper and aluminium, as it can be fastened with glue and is easier to cut into smaller pieces. The flexibility of this plastic means that it too can be used for a wide variety of piping, and that larger PVC pipes are often used in plumbing for the distribution of non-drinking water.

Both grades of PVC can be problematic to process when it comes to

injection moulding. By its nature, PVC is a heat-sensitive material; temperatures of 160-175℃ are required for the plasticising process.

When PVC is in a melted state, it also becomes reactive to other materials and gasses. A good example of this is PVC and Acetal (Polyoxymethylene). When these two materials are mixed in a melted state, it can cause an explosive reaction.

This added step, therefore, makes PVC harder to work with when injection moulding, so many other facilities choose to avoid it completely. However, at TCB Arrow, we have the skills, resources and capabilities to injection mould PVC in a variety of different forms, making it suitable for a wide range of applications.

Environmental Impact

When it comes to considering the environment, both materials have their perks. Whilst neither plastic is biodegradable, they’re each recyclable and can be reprocessed.

uPVC May just have the upper hand, though: in addition to being a good substitution for wood–meaning it doesn’t contribute to deforestation–uPVC also lacks the plasticisers which can leak out of PVC and cause environmental damage. This makes it the ‘cleaner’ choice of the two.

Conclusion

When it comes to the differences between uPVC and PVC,each has a level of durability that makes them great for piping, but uPVC is definitely the stronger and more environmentally sustainable choice. However, if it’s versatility you’re looking for then PVC is arguably more appropriate, as it has uses in not only plumbing but also fashion and entertainment.

Fundamentally, each performs well in their specific uses as a reliable and sturdy plastic. Whichever you choose will depend on its intended use. However, if it’s PVC you’re looking for, remember that

TCB Arrow fully understands and overcomes its challenges due to 35 years of trusted experience.

Having been established for 35 years, at TCB-Arrow we have extensive experience injection moulding a variety of thermoplastics.

We are a modern organisation providing components and assembly solutions in Thermoplastic and Elastomer materials. Visit our website to find out more.