Safe and Compliant Moulding Services for the Food & Drink Industry

TCB-Arrow provides plastic moulding solutions that meet the stringent safety and hygiene standards required in the food and drink industry. Our ability to work with food-safe materials ensures that all components are suitable for contact with consumable goods.

Services for the Food & Drink Sector:

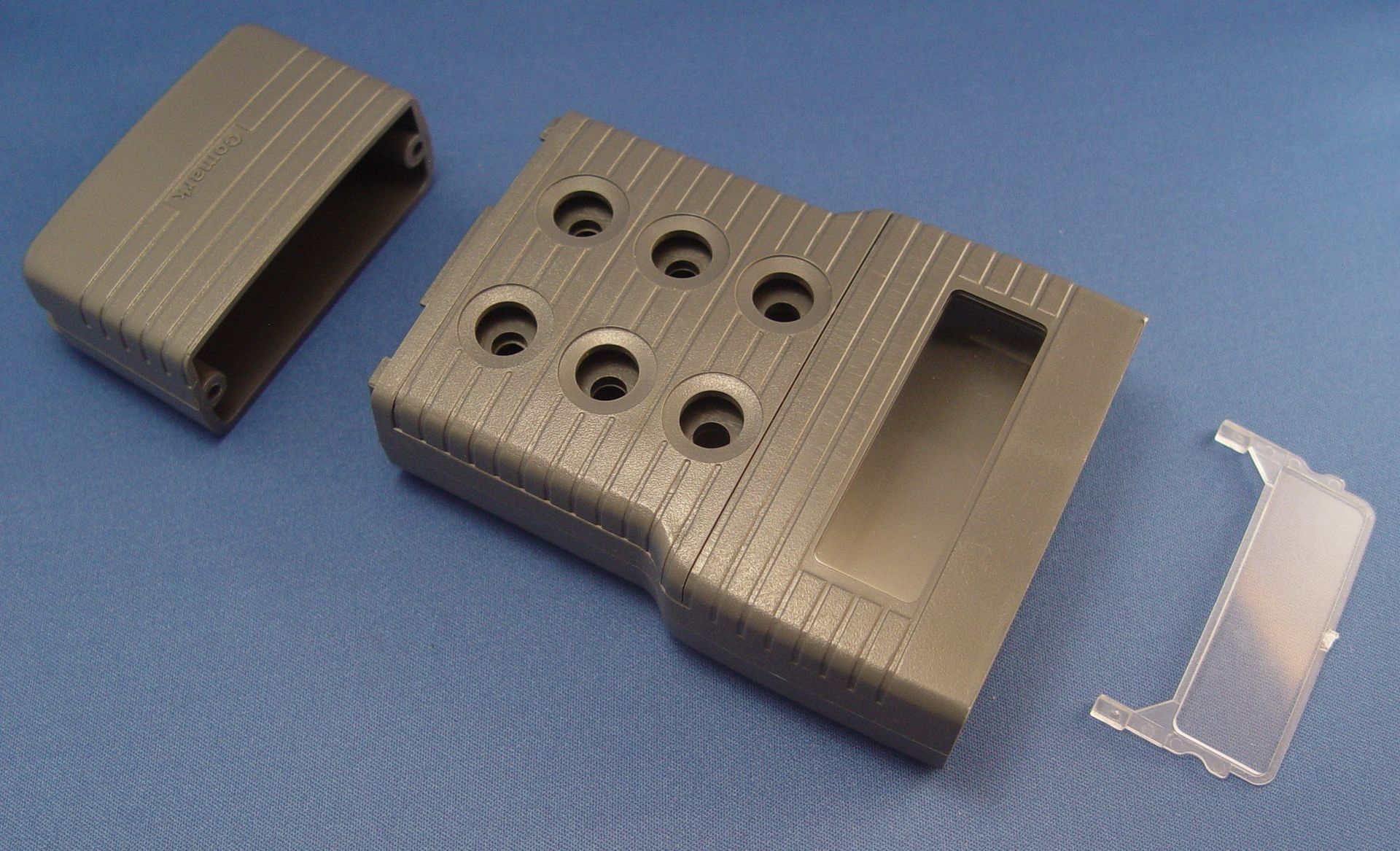

Thermoplastic Injection Moulding

Manufacturing components such as food-grade containers, dispensers, and packaging parts from FDA-approved materials.

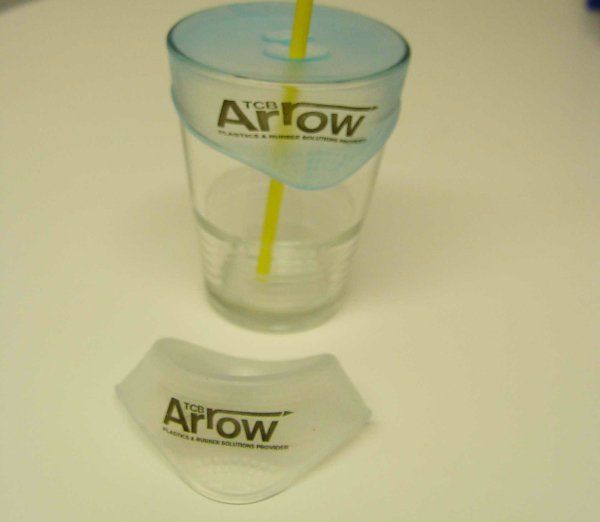

LSR Moulding

Producing silicone components for food processing equipment, known for their high-temperature resistance and hygiene properties.

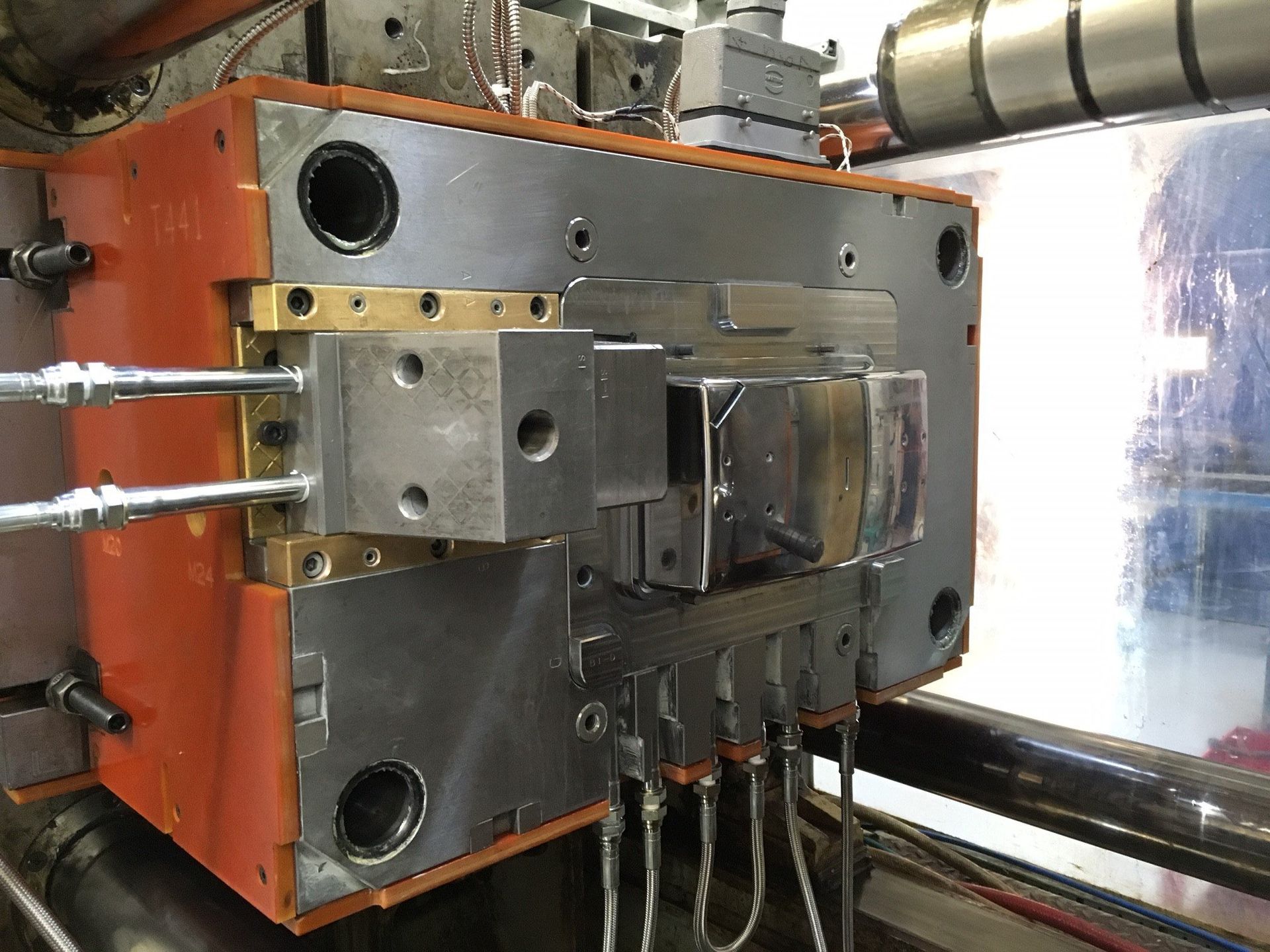

Developing mould tools specifically designed to meet the sanitary requirements of the food and beverage industry.

Offering cleanroom assembly and specialised packaging options to ensure products meet food safety standards.