Precision Moulding for Hygiene and Sanitation Products

In the hygiene sector, TCB-Arrow produces high-quality moulded parts used in sanitation products and equipment. Our moulding expertise allows us to deliver components that meet the industry's strict cleanliness and durability standards.

Hygiene-Specific Services:

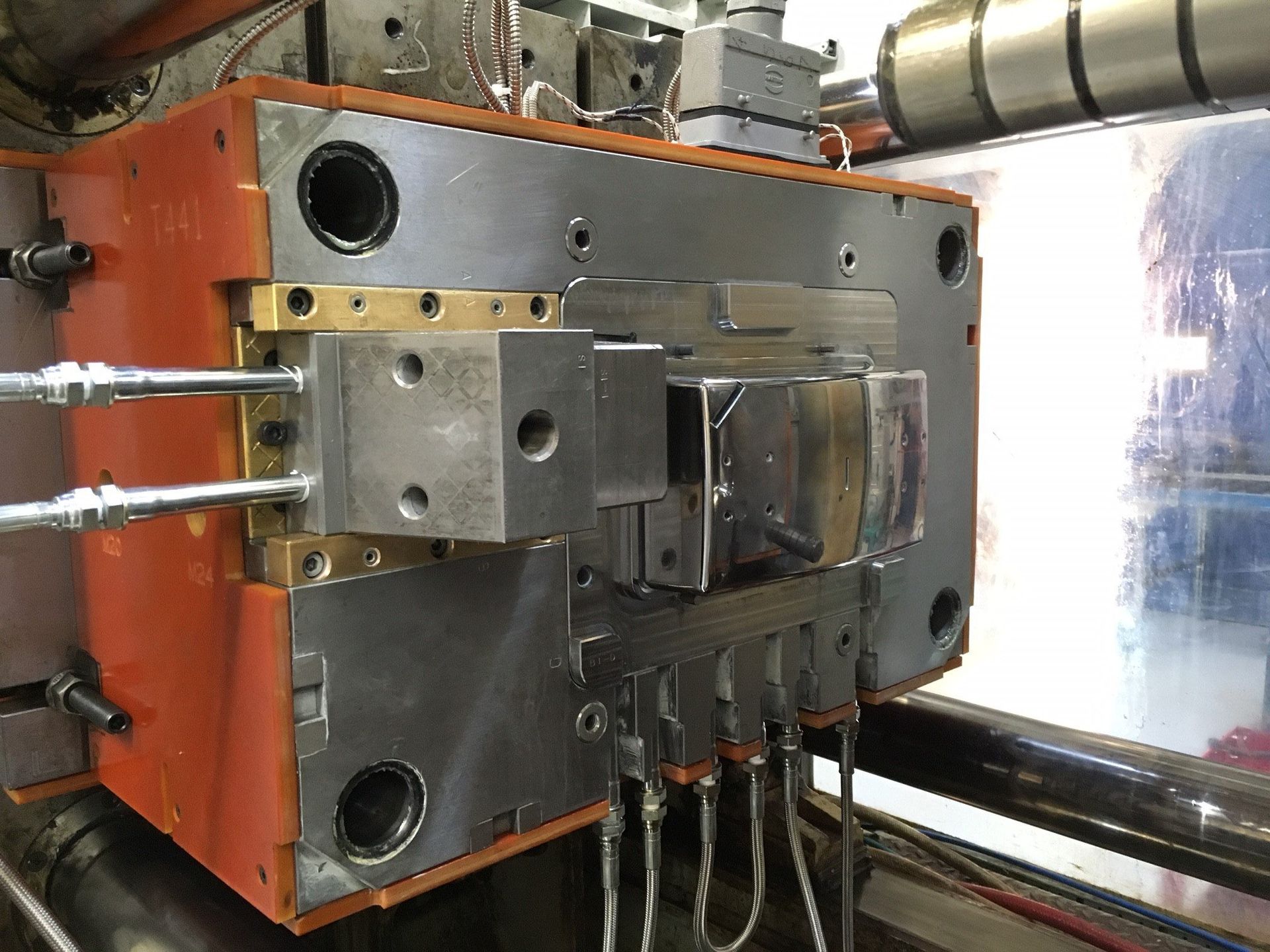

Thermoplastic Injection Moulding

Producing parts for hygiene products, including dispensers, cleaning equipment, and protective coverings.

LSR Moulding

Ideal for creating flexible and durable silicone components, such as seals for hygiene equipment and parts for cleaning devices.

Precision tooling to support the manufacture of products that comply with hygiene standards.

Providing assembly and packaging solutions that maintain the sanitary quality of the products.