Medical-Grade Moulding Solutions for Healthcare Applications

TCB-Arrow is a trusted provider of moulded components for the medical industry, meeting the sector's strict regulatory requirements. Our ability to work with medical-grade materials ensures the safety and effectiveness of our products.

Medical Services:

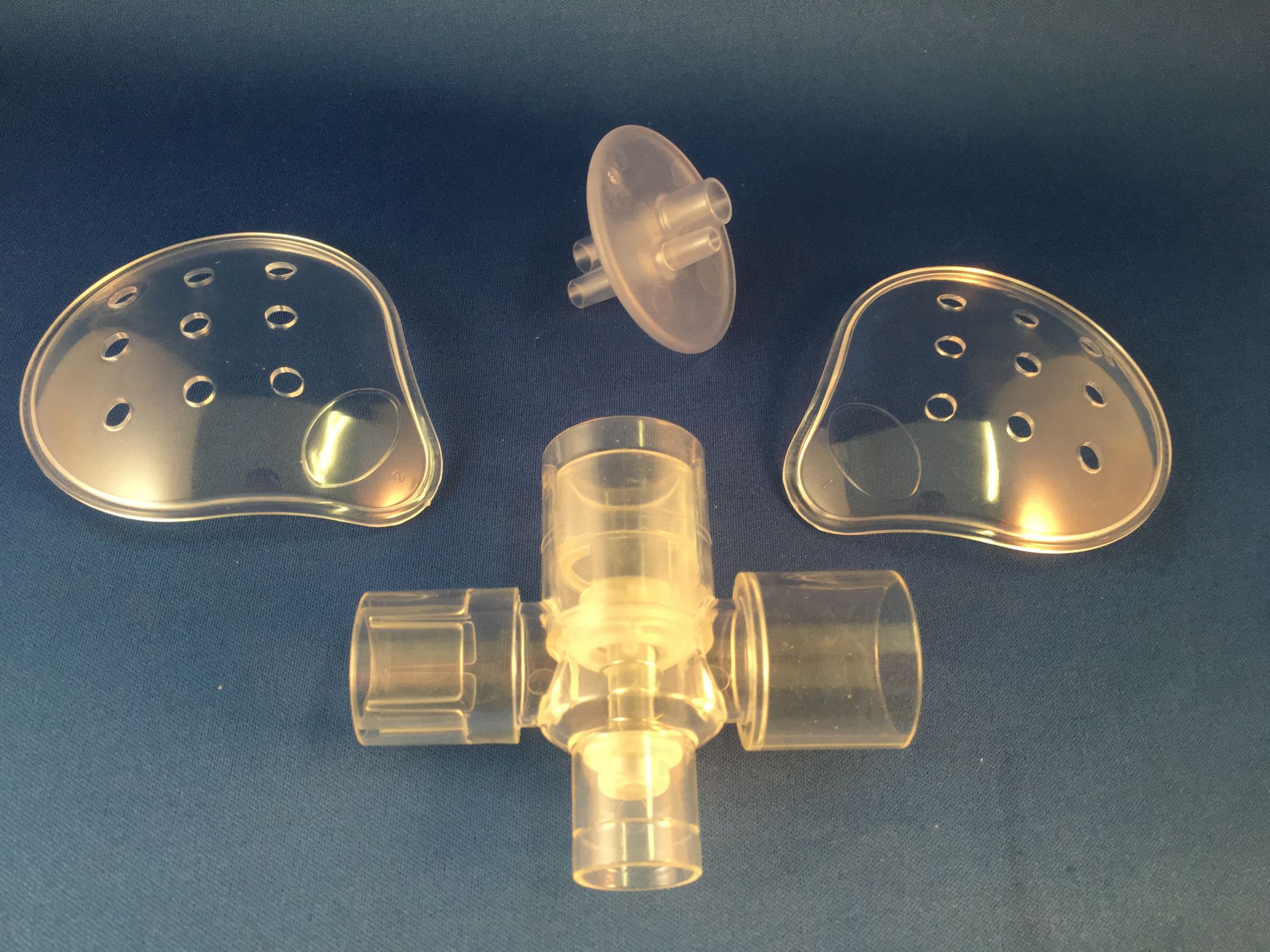

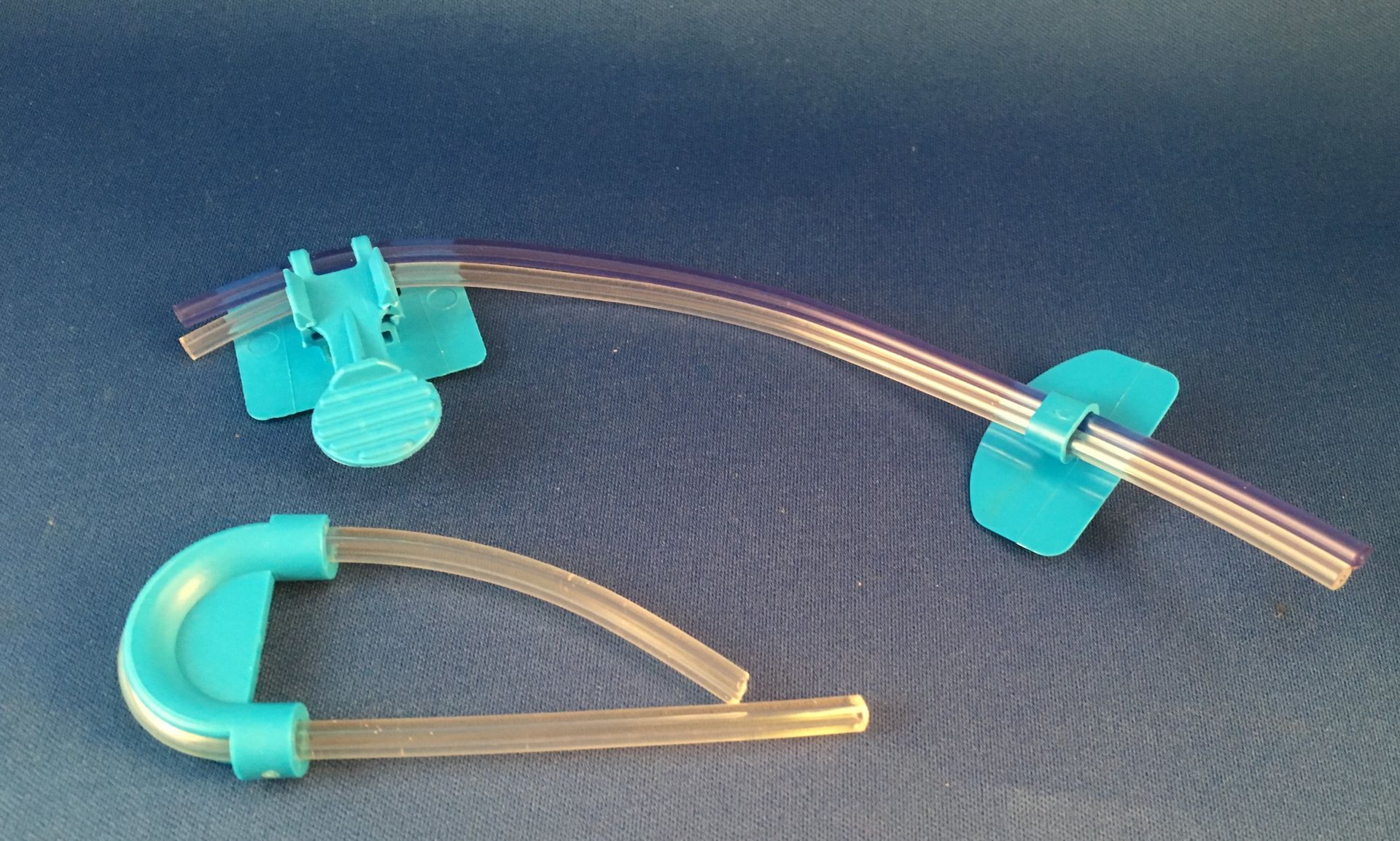

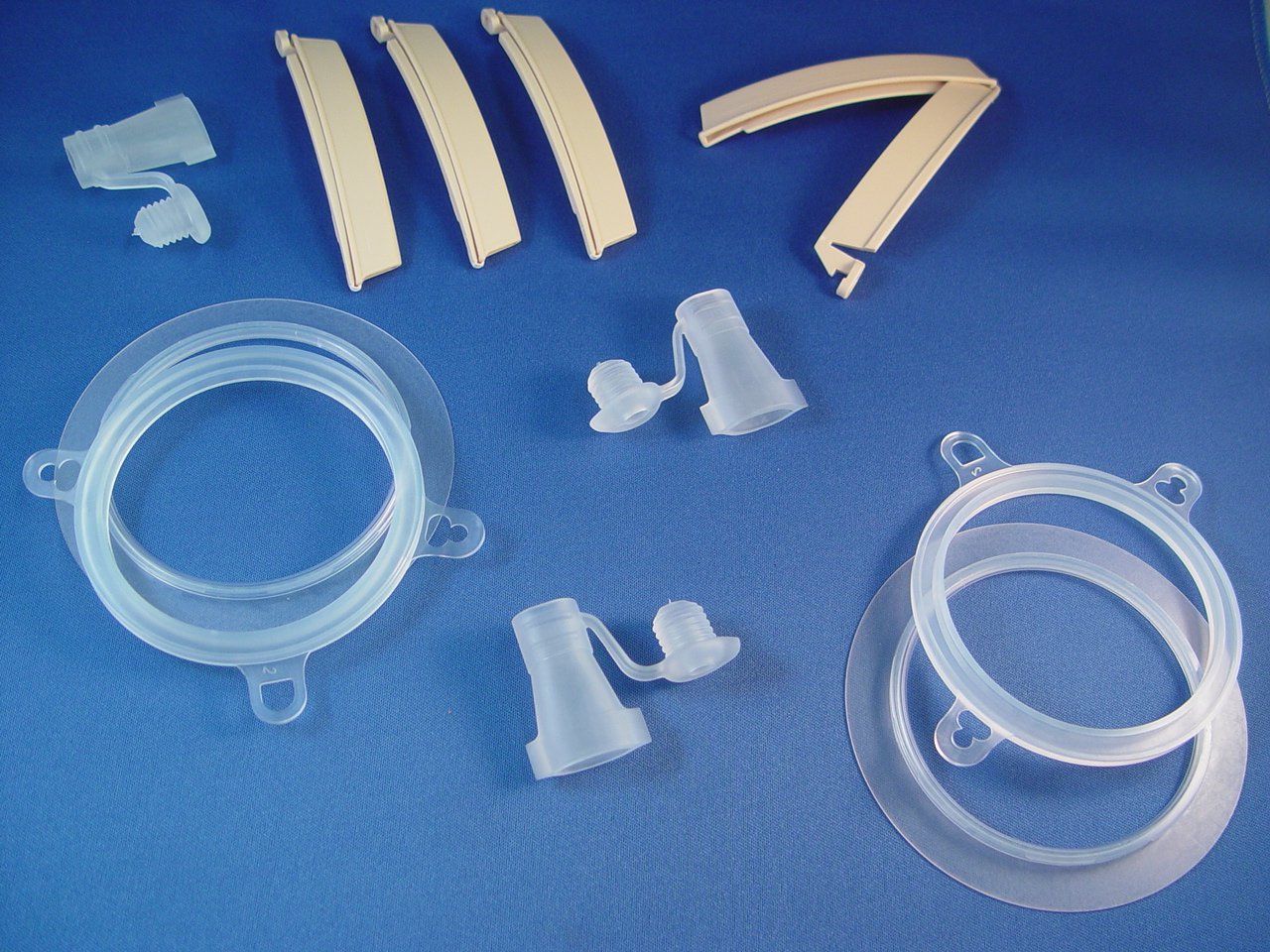

Thermoplastic Injection Moulding

Manufacturing components for medical devices, diagnostic equipment, and patient care products, using biocompatible materials.

LSR Moulding

Producing silicone components with FDA/USP Class 6 approval for medical applications, such as airway management systems and surgical tools.

Precision tool making for medical moulds, supporting the production of components with stringent tolerances and cleanliness standards.

Cleanroom assembly, testing, and packaging services to ensure medical products meet regulatory requirements.