Four Benefits of Using Plastic in the Medical Industry

Plastic is one of the most widely-used materials on the planet, favoured for its versatility and cost-effectiveness, which allows it to be used in all manner of applications. In the medical industry , different variations of plastic are enabling healthcare providers to ensure that patients continue to receive a high quality of care, while cutting costs along the way. These are just some of the benefits of using plastic within the medical industry.

Infection Resistance

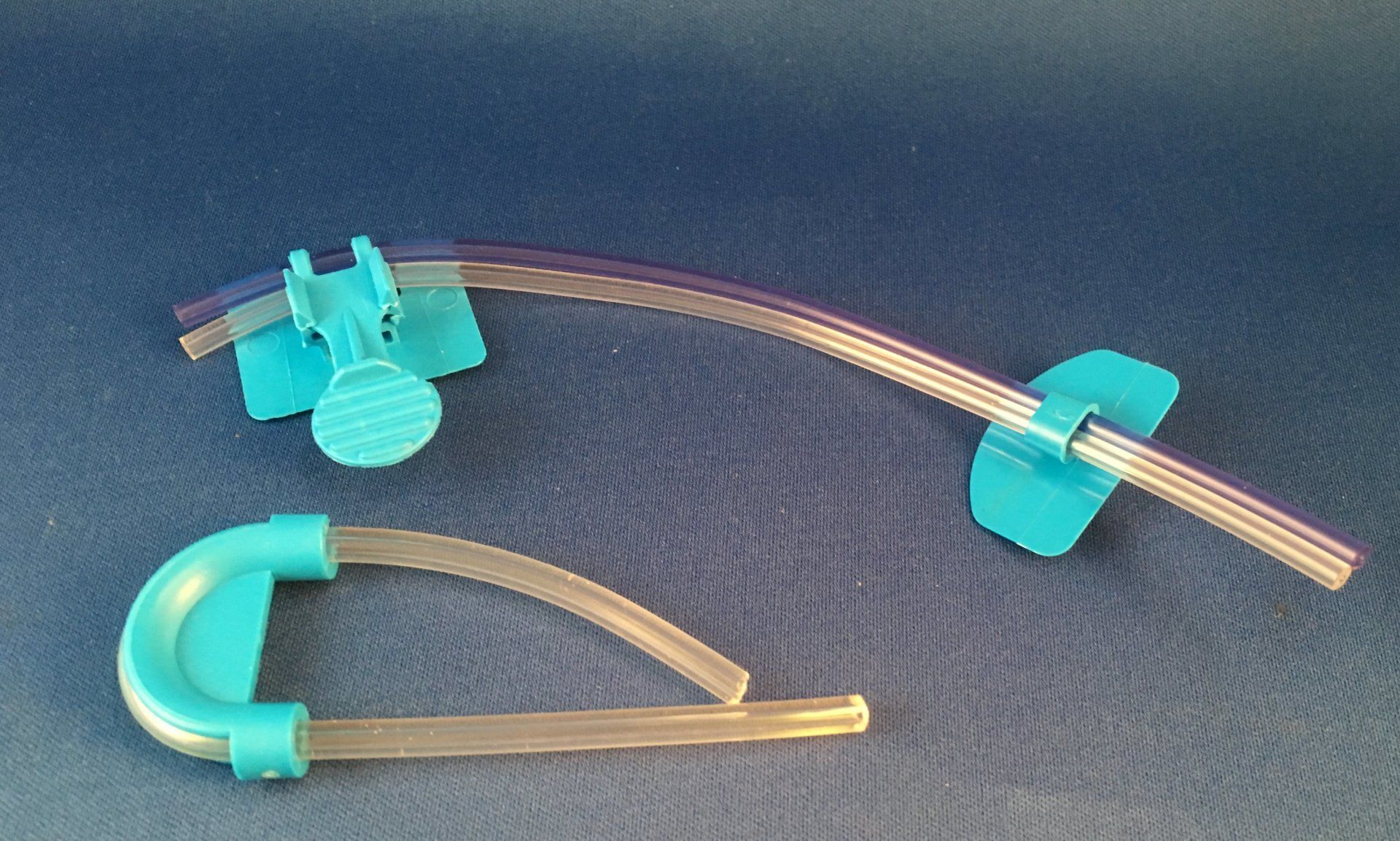

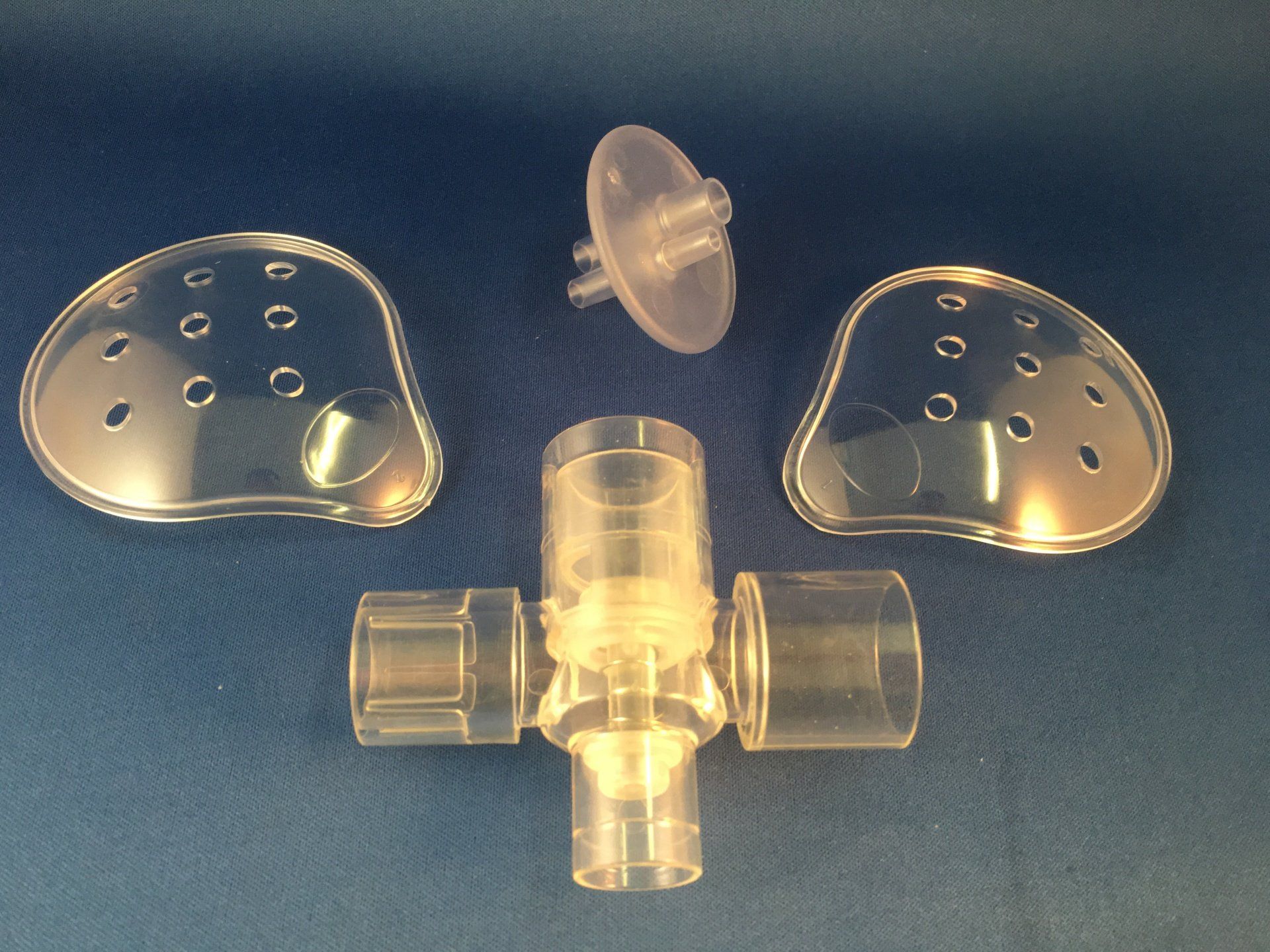

Plastic has greatly improved safety in the medical industry, where good hygiene is of paramount importance. The inherent sterility and inertness provided by plastic helps stop the spread of diseases in hospitals, so it’s no surprise that many different items found in the industry are plastic - bedpans, IV tubes, syringes and eye patches to name a few. Specifically, antimicrobial additives in the polymer can help to repel and kill bacteria on exposed surfaces.

Containment and Safety

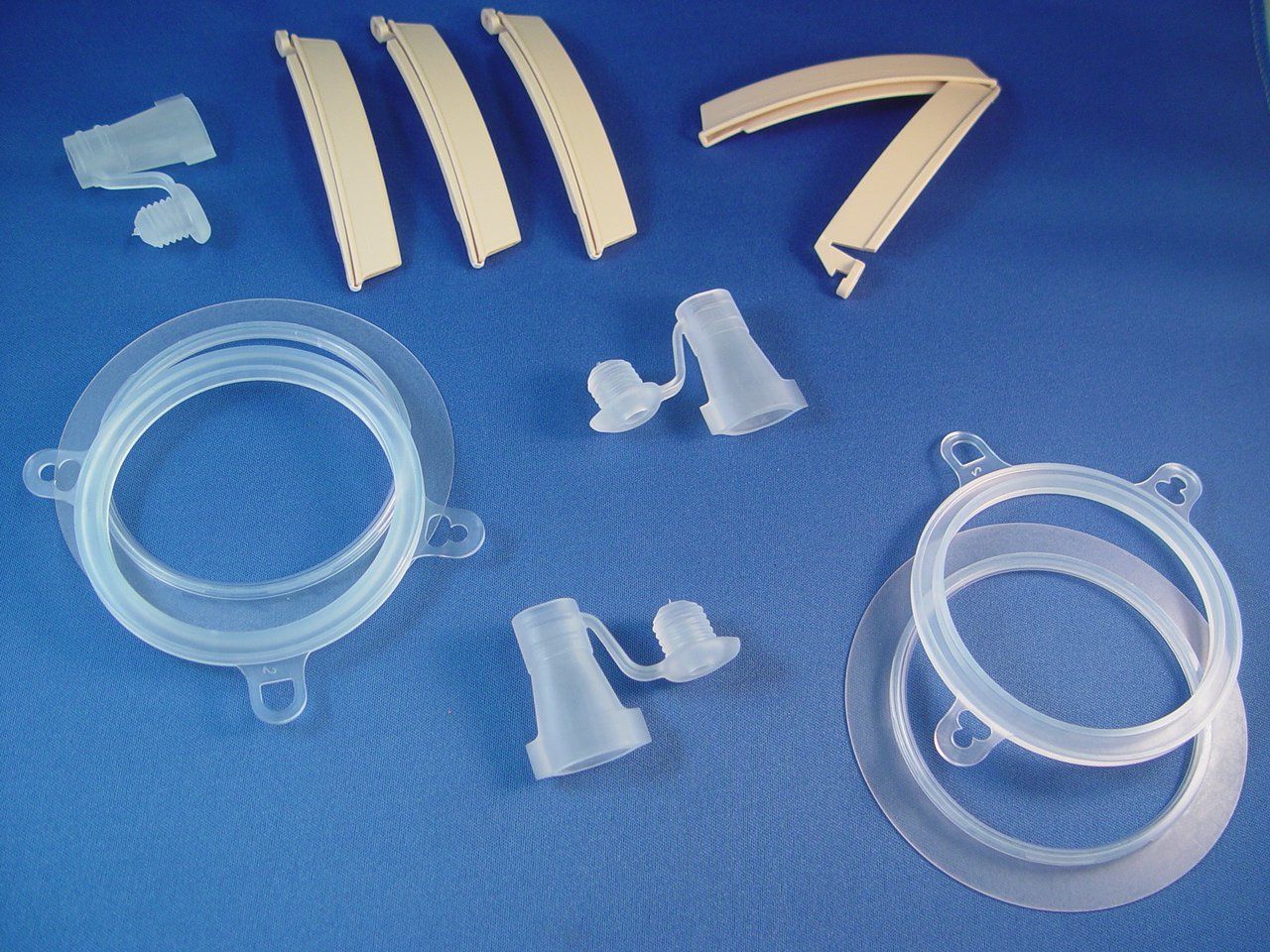

Thanks to the aforementioned hygienic properties of polymers, mouldings make excellent containers and material handling devices. But it’s more than just its sterility – many plastics can resist incredibly hazardous substances, while also being far safer to transport than something like glass, which has the potential to shatter. Plastics can also help to preserve the integrity of a container’s contents, making them ideal for protective coverings.

Cost-Cutting

Plastic devices are generally cheaper to produce than metal ones, due to cycle times (production rates) and material cost, plastics parts and components are saving people money all across the industry. These reusable plastics are easier to replace and have a longer life than single use metal devices.

Innovation

Plastic technologies are enabling engineers and medical inventors to create new devices from the smallest micro-moulded parts. Thanks to this, plastics are being used in surgical devices and procedures, and are being used more and more in devices such as pacemakers, joint replacements and stents.

If any of our services within the medical industry or other industries are of interest, don’t hesitate to get in touch on +44 (0)1276 679394 or drop us a message on enquiries@tcb-arrow.co.uk.