Do You Know these Everyday Items that are Injection Moulded?

Injection moulding is one of the most common manufacture methods used to create an array of everyday plastic objects. The versatility of injection moulding means it can be utilised to create intricate and tiny mechanical parts, to huge objects and casings.

Despite how complicated injection moulding plastic might sound to a consumer, it will have created a variety of apparently simple items found all around you. Here are a few examples:

1/ Smartphones

Are you looking at this on your smartphone right now? Although not all phones are made of plastic, most smartphones contain tiny and very intricate injection moulded plastic parts. Most electricals rely on injection moulded plastic to operate reliably, safely and consistently.

5/ Medical Equipment

Injection moulding is used to manufacture both single use disposable and reusable parts for the medical industry. At TCB-Arrow we manufacture medical parts in both Liquid Silicone Rubber (LSR) and Thermoplastics.

3/ Packaging

From fruit salad packaging and waterbottles, to cosmetics tubes and shampoo bottles, injection moulding is used to produce a huge range of food , hygiene and cosmetic packaging. We have produced an array of hygiene related products, such as fragrance air fresheners, soap dispenser and odour neutraliser devices.

2/ Cooking Utensils

Plastic bowls, plates, cups and eating utensils are generally injection moulded to create precise and durable kitchen equipment. Silicon spatulas, spoons and whisks are also injection moulded to create robust and heat-resistant cooking utensils.

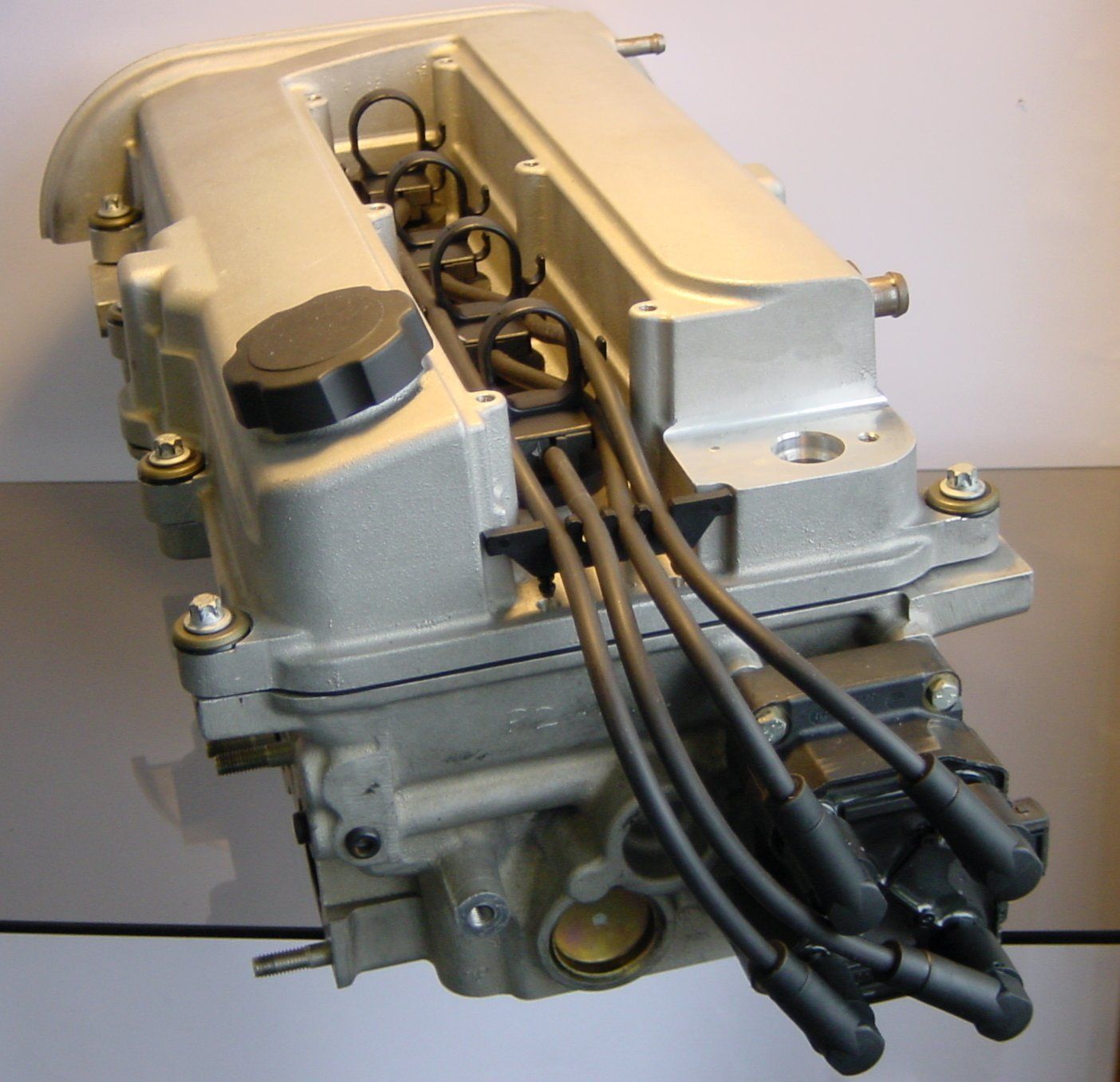

5/ Automotives

When you are sitting in your car, you are surrounded by injection moulded parts. From the dashboard to the tiny buttons on your radio, most of the components surrounding you are injection moulded plastic. Not only that, but ignition leads, insulator boots and car number plate components are created through the same manufacturing process. Even the car bumper is probably injection moulded !

TCB-Arrow are specialists in the precision manufacture of Injection moulded parts from low to high volume production here in the UK. With a wealth of experience and expertise, we offer over-moulding and multi impression manufacture from very small to large size mouldings across the full range of Thermoplastics. Get in touch on 01276 679394 or drop us an email at enquiries@tcb-arrow.co.uk.