Stick+Store Dual-Bladed Duo Squeegee for InHouse

TCB-Arrow have been working with product inventor Steve Briton-Williams to produce a Dual-Bladed Duo Squeegee for InHouse's Stick+Store shower products range.

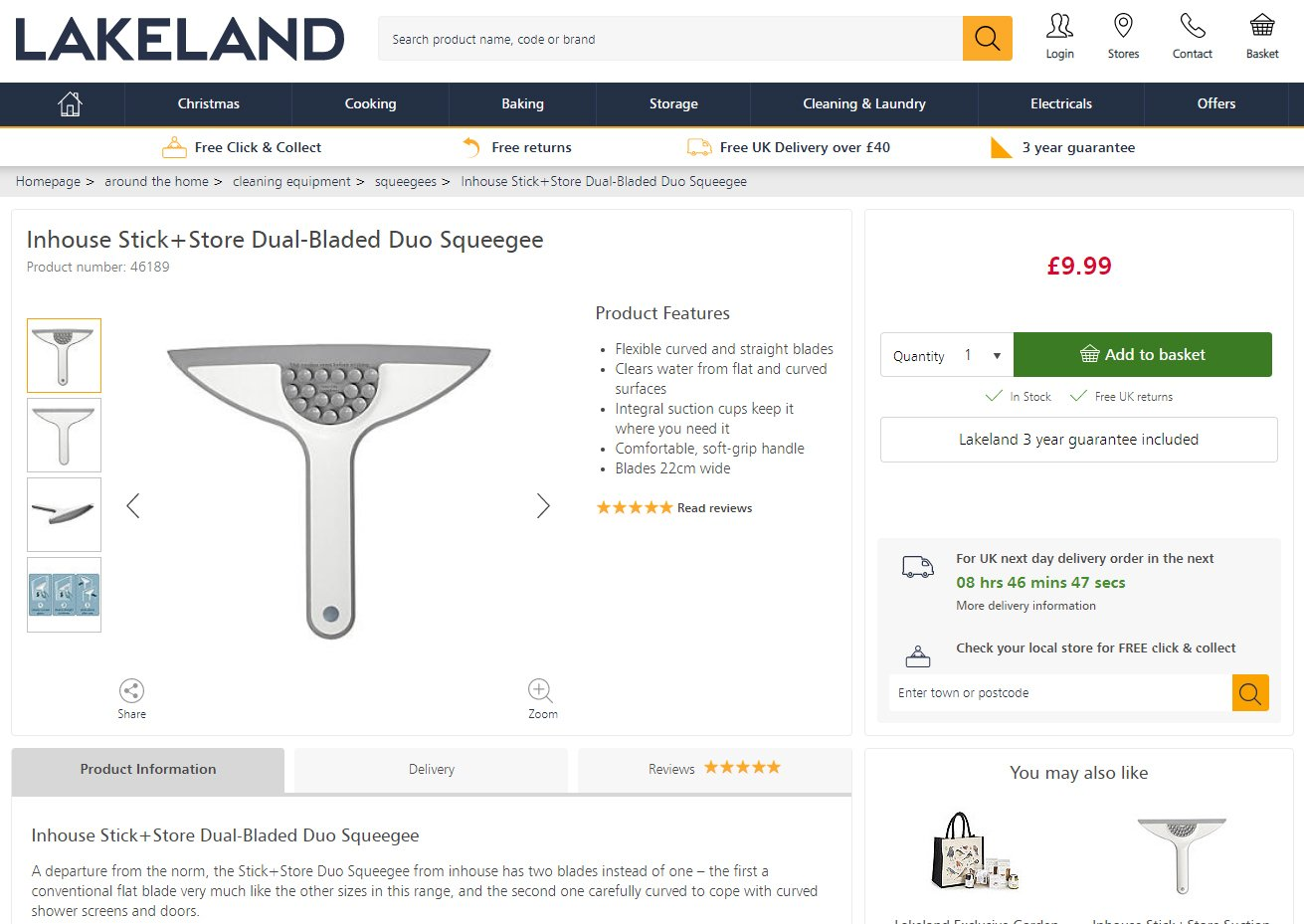

TCB-Arrow has successfully helped product inventor Steve Briton-Williams develop an additional Duo Curved and Straight shower Squeegee to join his current range of InHouse Stick+Store shower products. The first pallet of 1,000 parts were manufactured, packaged completed for dispatch to Lakeland on the 10th October 2019. The new product launch took place on the following Monday and by later that week it had jumped to Lakeland’s No.1 spot by product type!

This Duo Squeegee now complements the smaller Mini Squeegee and Larger Squeegee. The whole range has a clever patented integral suction cup system to keep it where you need it, with a comfortable soft-grip handle. The design includes two blades instead of one; the first a conventional flat blade very much like the other sizes in this range. The second one is carefully curved to cope with curved shower screens and doors. Its soft double blades also help clear water droplets from tiles, mirrors, windows, flexing as they travel over the surfaces you’re cleaning, to ensure not a drop or scratch will be left behind.

TCB-Arrow specialise in over moulding in both thermoplastics and liquid silicones, working to tight tolerances and high cosmetic finishes. TCB-Arrow strengths are working with customers from initial concept through to full production.We love the challenge of new plastic moulding projects! Don't hesitate to get in touch on 01276 679394.