How Are You Using Silicone in Everyday Life?

When most people think about the silicone items in their home, kitchen utensils such as cake cases, spatulas and non-stick products usually come to mind. However, there are a range of unusual and unexpected items in your house that are enhanced by including silicone, constantly improving our way of life. Here are a couple of ways silicone makes its way into your household:

It’s literally surrounding you. Silicone is used in building and construction, able to bond materials such as concrete, glass, granite, steel and plastics, enabling them to work better and last longer. These silicone sealants can absorb pressure and movement within engineering, allowing for more innovative architectural designs. It also helps protect materials and joints from moisture, heat, corrosion, sunlight, ultraviolet radiation, pollution and other chemicals.

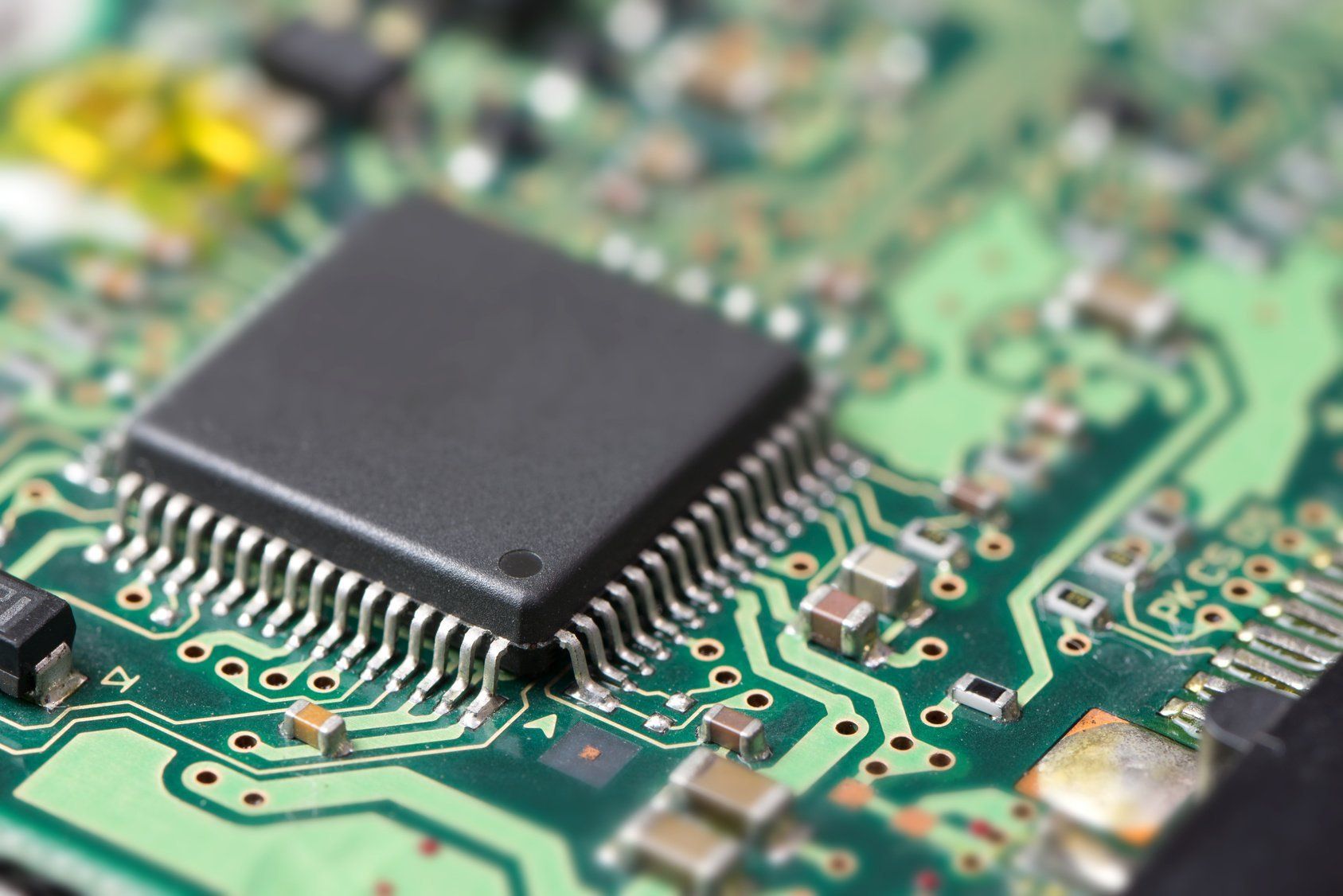

You’re looking at or holding silicon right now. Silicone plays a huge part within the electronics industry. Silicon is a semi-conductor, meaning that it can conduct electricity only in certain conditions and acts as an insulator under others. These characteristics make it an ideal material for making transistors that amplify electrical signals. Coatings for electrical products, such as keypads, keyboards and copier rollers, as well as the hard coatings for computers, facsimile machines, telephones and home entertainment equipment are all made from silicone.It’s not just silicon spatulas in your kitchen. Silicone is great for cooking utensils, as it has no odour and can can go from the freezer to the oven, microwave or dishwasher without affecting the quality of the product or the food, however it is used in other aspects of your kitchen too. Household cleaners and polishers often include silicon to enhance shine and spread easily.

Use a car to get to work every day? Silicone adhesives and coatings ensure that vehicle exteriors are more resistant to rain, wind, salt, abrasion, ultraviolet radiation and chemicals. Joints last longer and overall maintenance and repair is less costly. Silicone is used in a huge range of car parts, such as airbags, hydraulic bearings, ignition cables, shock absorbers and headlamps.

You might be wearing it! Silicone is used in a variety of make-ups, cleansers, shampoos and other personal care products to improve shine and texture.

At TCB-Arrow we have developed Liquid Silicone Rubber Moulding over the last 12 years. We aim to achieve the optimum tooling solution to meet our customer's criteria, so no matter for what industry the silicon will be used for, we know we can help. Give us a call on 01276 679394 or drop us an email at enquiries@tcb-arrow.co.uk to speak to one of our expert team.