POLYPROPYLENE GUIDE

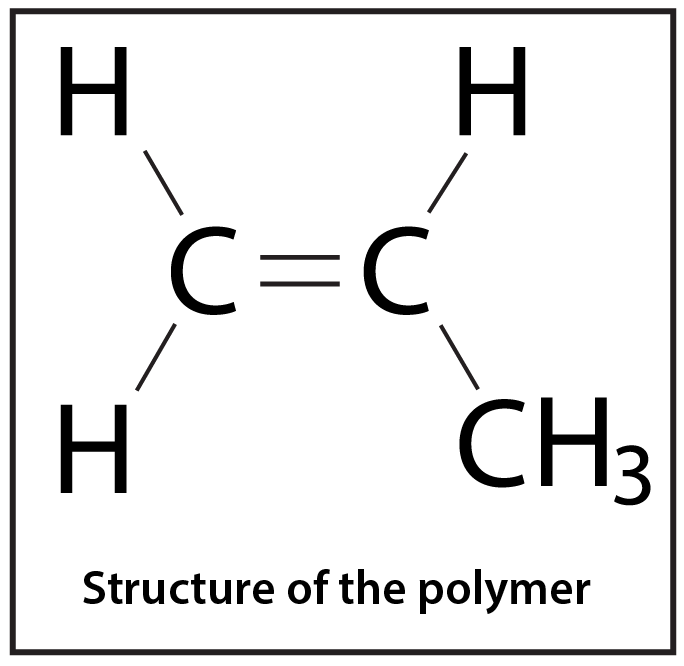

| Name: | Polypropylene |

|---|---|

| Abbreviation: | PP |

| Recycling Code: | 5 |

| Structure: | Semi Crystalline |

| Group: | Commodity Plastic |

| Common Industries: | Packaging, Automotive & Medical |

| Key Features: | Living Hinge, Chemical Resistance |

Properties

The general properties of polypropylenes make them attractive for a wide range of applications – they’re strong, semi-rigid, have high thermal resistance and are easy to process. They’re also recyclable, making them a strong choice in the journey to achieve greener manufacturing

There are two main categories of Polypropylene available: Homopolymers and Copolymers. Homopoylmers have a high strength-to-weight ratio and are lightweight, but low temperatures cause them to become brittle. Meanwhile, copolymers are split into block copolymers and random copolymers.

Block copolymers have co-monomer units arranged in a regular pattern, and contain around 5 - 15% ethylene, which improves its low temperature performance and impact resistance. However, they’re more opaque and have less gloss. Contrastingly, random copolymers have a lower ethylene content (1 - 7%) and an irregular chemical structure, making them suitable for when enhanced clarity, greater flexibility or a lower melt temperatures may be required.

Finishing

Polypropylene is not generally suited to printing, although there are treatments available to prepare them for ink. There are also various adhesives available to make it possible to connect polypropylene mouldings. Mouldings may also be machined if this is required.

Additives

The properties of polypropylenes can be tailored by combining various additives. One of the most common examples is talc. Using a talc additive within polypropylene is a cost-effective way to reduce the dimensional inconsistencies brought on by shrinkage. Alternatively, adding glass fibres will make polypropylenes more resistant to stress cracking, and give them enhanced impact resistance and more rigidity.