INNOVATION CENTRE

Welcome to the Innovation Centre, where we'll take you through some of the processes we use to overcome any challenges or obstacles within a variety of projects.

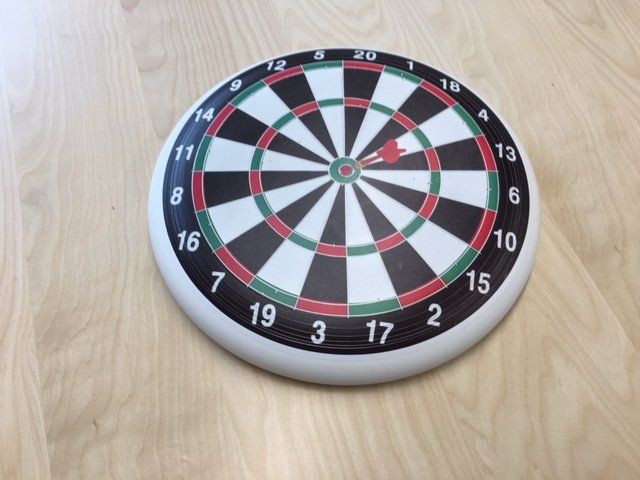

In-Mould Labelling

Many plastic products feature labels or images on them. Often these are just images or stickers added to the final product, but thanks to in-mould labelling, we're able to integrate the graphics within the plastic mould. Recently we used in-mould labelling while creating the mould for these bespoke frisbees. We produced 23 different designs using the process.

The Process:

We begin by purchasing the label already printed and cut out. The mould tool then picks the label from a stack to place into the tool, which is held in place with electrostatic forces. Plastic is then injected onto the label, filling the cavities. When the tool opens after the process is completed, the mould is ejected.

In-mould labelling can be used on both flat and curved surfaces, and can work with high-resolution prints and multiple colours.

Golf GPS Device

A cutting-edge device that allows the wearer complete control over their golf game. It uses the highest grade smart GPS chip on the market. The data collected through the device allows the wearer tournament-level analysis of their game. You're able to play on any course, worldwide, with no restrictions. The device drives your improvement through performance analysis, from clubs to tee shots and approaches.

It is an incredibly innovative product, using GPS to accurately track your golf ball. It features a database of 40,000 courses with detailed mapping of individual features.