Liquid Silicone Rubber (LSR) Injection Moulding Process Guide

What is Liquid Silicone Rubber (LSR)?

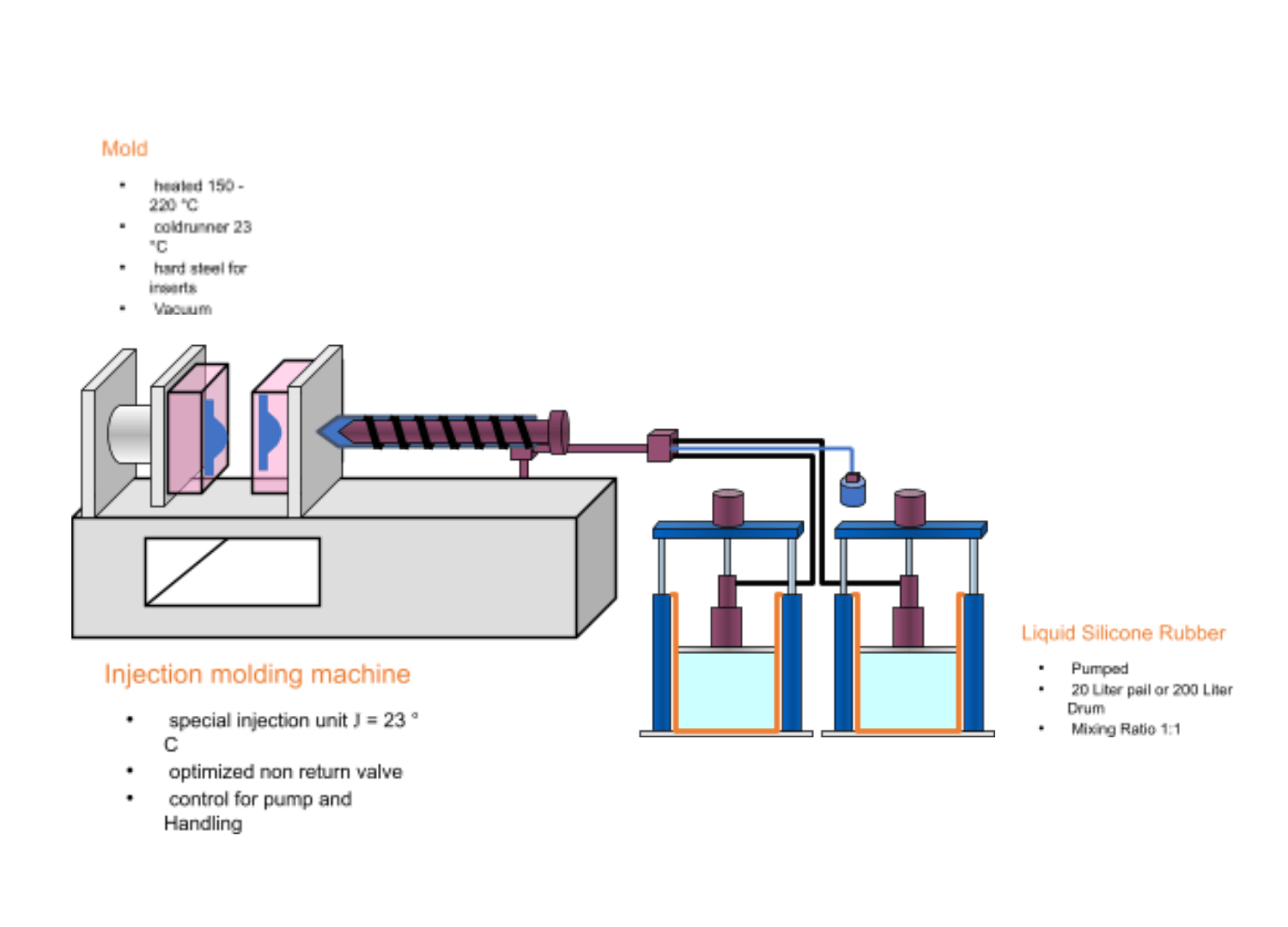

LSR is a Thermo-Set material, meaning that heat is required to ‘cure’ the material by cross-linking polymer chains (vulcanising). The injection moulding of LSR involves mixing the two-component compound together, which is then heat-cured in the mould with a platinum catalyst to produce a finished LSR part.

The Advantages of Liquid Silicone Rubber Moulding:

LSR is particularly popular for products for the Medical and Automotive industries, due to its good physical properties that include:

- A wide temperature range (–50 up to +250 °C)

- Very good temperature stability and resistance

- Excellent physiological/Hypoallergenic properties

- Good ageing and weather resistance (Ozone- and UV-resistant)

- Very good dielectric properties

- Good clarity/transparency and easily pigmentable if required

- Low viscosity that allows the material to flow easily into thin and complex areas of the mould

- Suitable for high-volume production

- Short cycle times compared to compression moulding (higher production rates)

How does LSR Moulding Work?

An LSR moulding tool is fabricated using CNC machining to create a high-temperature tool built to withstand the LSR moulding process. Due to the flexible nature of LSR, parts are generally extracted from the cavity by air ejection or robot, ejector pins are less common in the mould design.

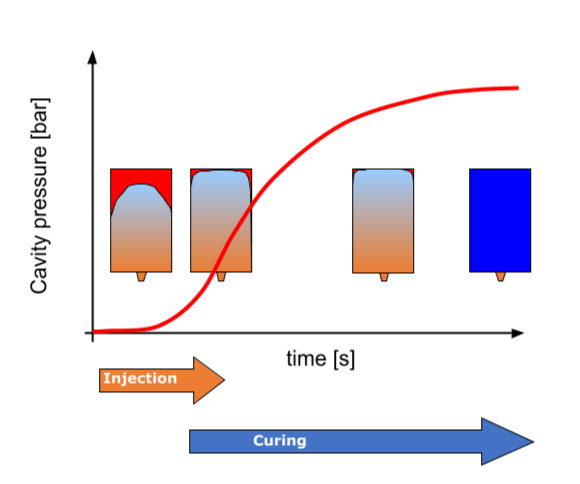

The material is injected into the tool cold. The mould tool has heater cartridges fitted to heat the tool, enabling the LSR to cross-link (vulcanise) and solidify. Insulation plates prevent heat loss and ensure the heat is contained in the tool. This step is called the curing stage, dependant on the silicone grade used and the section thickness of the part.

Unlike conventional

thermoplastic injection moulding,

LSR injection moulding requires little to no holding time, and the cavity only needs to be 90-95% filled. Cavity pressure is created by the expansion of the LSR as it cures, providing the finished part surface finish. This is shown below:

For more information on the liquid silicone rubber (LSR) moulding process or our other plastic injection moulding services, visit our website.

GET IN TOUCH

Contact Us - Footer (All pages)

We will get back to you as soon as possible

Please try again later